Product introduction

Monitor your thin film deposition and vacuum treatment process in real-time with Riber Magnification Inferred Curvature (MIC) tool

- RIBER – EZ-CURVE®

- RIBER – EZ-CURVE® Software

- RIBER – EZ-CURVE®

- RIBER – EZ-CURVE® Software

Main benefits

- In situ stress, bow and curvature measurement, in real time

- Set precise growth patterns and monitor deviations

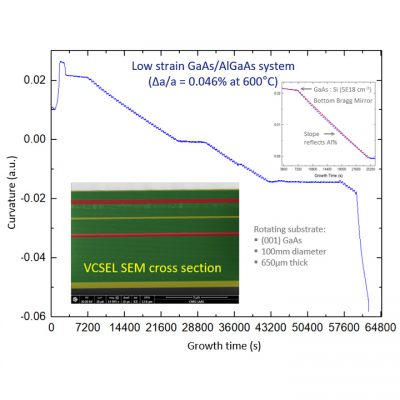

- Detect specific growth events and retrieve fundamental knowledge about growth mechanisms

- Suitable for various thin films deposition techniques (CVD, MBE, PVD,…) and vacuum treatment process (plasma etching, annealing, quenching …)

- Unrivalled curvature sensitivity

- Simultaneous spherical and cylindrical bowing, anisotropy measurement

- Compatible with low lattice mismatch systems like AlGaAs/GaAs

- Thick wafer compatible -up to few mm

- Highly stable & alignment-free measurement

- Wide-range wavelength source – immune to reflectivity change, no need to adjust exposure time

- Immunity to wafer flatness – possible use with patterned wafer

Key features

| Parameter | Specifications |

|---|---|

| Curvature range (min – max) | 0,0008 – 200 000 km-1 |

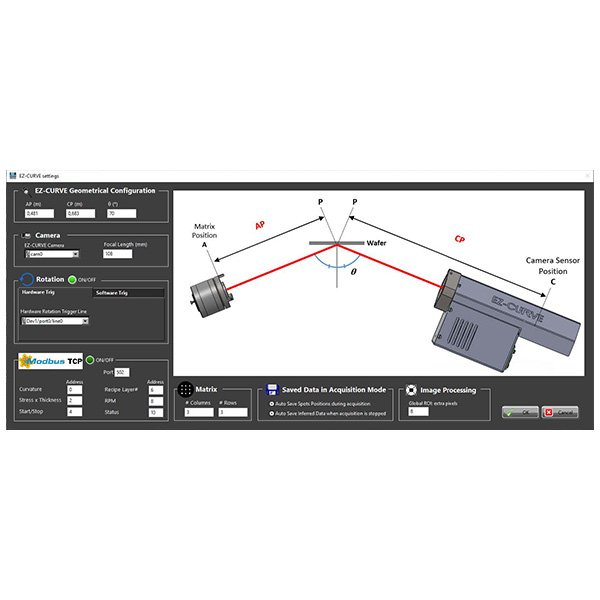

| Sensitivity (1-std dev) | Up to 8×10-7m-1 (5×5 matrix, 5s integration/ 500 points –θ= 70°) |

| Measured standard deviation | 8.33×10-6m-1(θ= 0°) // 2.85×10-6m-1(θ= 70°) |

| Radius range (max – min) | 1 250 000 -5×10-3m |

| Source lifetime | 50 000 h |

| Measurement frequency | 100 Hz |

| Rotation speed range | 0-100 rpm |

| Viewport to sample distance | Adjustable from 75 mm – depending on vacuum chamber dimensions |

| Flexible installation angle on the reactor | 0 – 70° |

Software

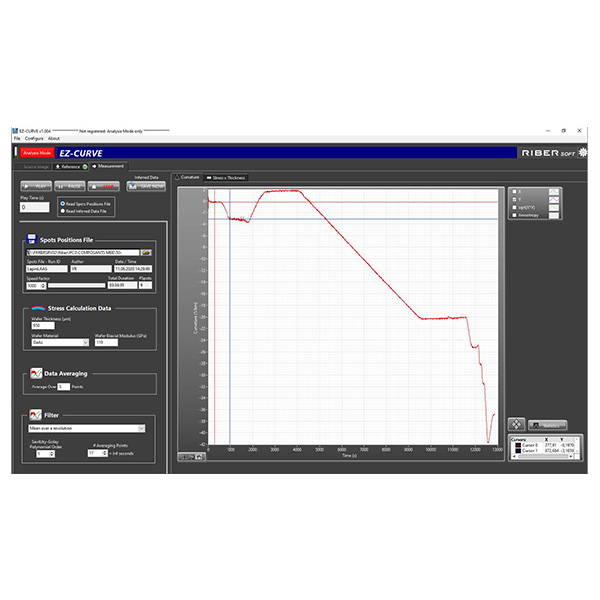

- Curvature, Stress, Phase and Anisotropy measurement & display

- Intuitive data acquisition

- Powerful data saving functions

- Real time mode up to 100 fps

- Flexibility to share data with other software incl. Riber Crystal XE

- Post-processing and data treatment

- Remote modbus interface

References

Find out more about EZ-CURVE here :

- Nature Scientific reports : Magnification inferred curvature for real-time curvature monitoring

- Journal of Applied Physics : Links between bismuth incorporation and surface reconstruction during GaAsBi growth probed by in situ measurements

- ACS Applied Energy Materials: Thickness Limitation of Band-to-Band Tunneling Process in GaAsSb/ InGaAs Type-II Tunnel Junctions Designed for Multi-Junction Solar Cells

https://www.youtube.com/watch?v=J3uP8p8hyqU

https://www.youtube.com/watch?v=J3uP8p8hyqU